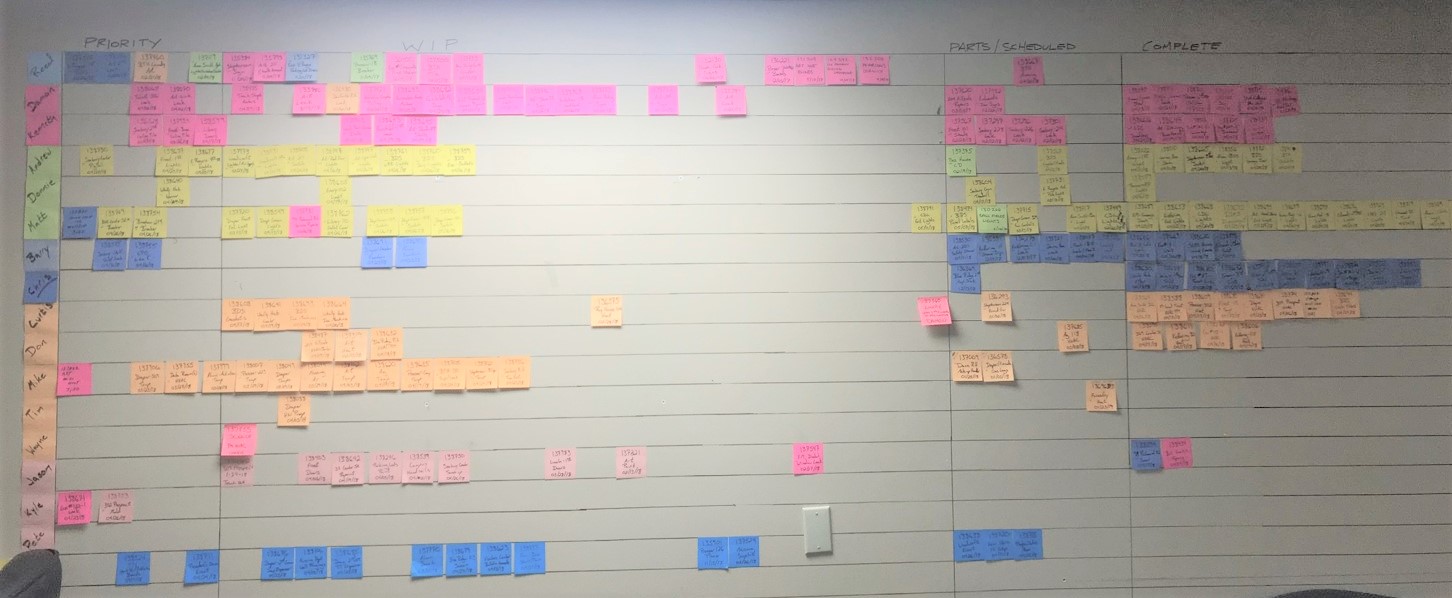

WIP Board

WIP boards are used to manage work in progress. These are used for individual work, teamwork, or management. The Continuous Improvement team helps determine WIP board needs and manages installation.

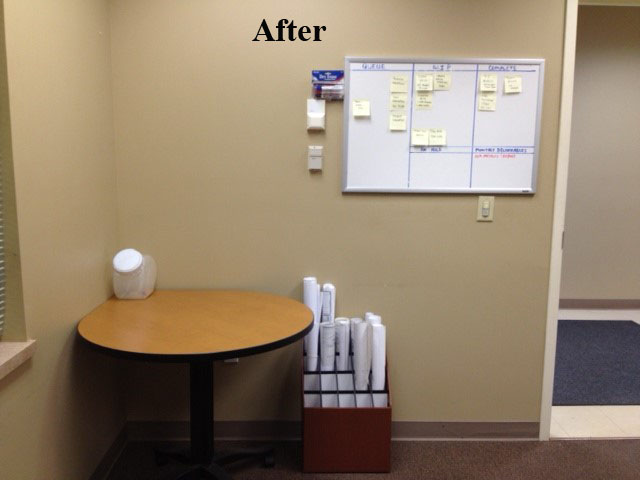

Facilities Management WIP Board

“The WIP board has been a very useful tool for me as a maintenance scheduler. It provides me with a very quick and easy to access reminder of who is responsible for what. It also provides me with a general idea of the progress toward completion of each task. On top of the benefit to me, the technicians use it as a central hub from which they gather and share knowledge about their progress and help schedule the services of other technicians when needed. On a daily basis I use it nearly as much as any other tool at my disposal save for my PC.” -Jeffrey Linville

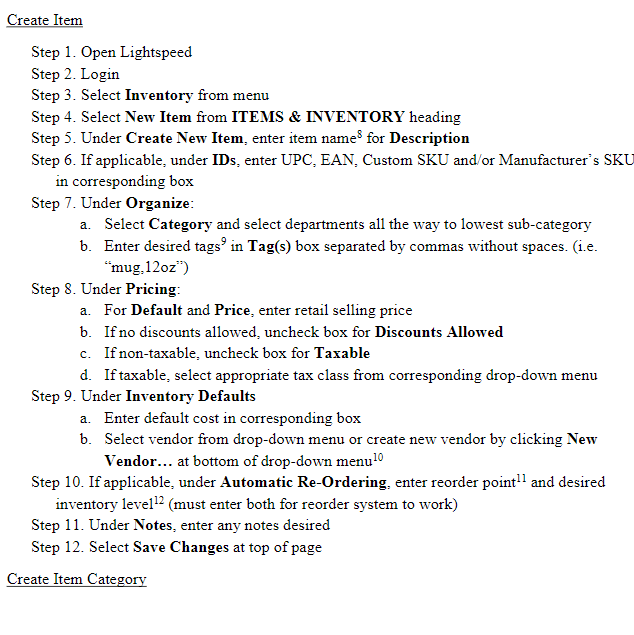

Standard Work

Standard work is used for documenting procedures. Standard work is utilized for offices, student labor, or any other process. The Continuous Improvement team can help establish standard work for your department.

Lightspeed Standard Work

The Lightspeed point of sale system is used at most the retail centers on the Berea College campus. Standard work was created to assist with the operating procedures for running each retail center.

5S Projects

5S projects focus on creating a clean and orderly workplace. This can be a personal work-space, digital or hard copy files, or storage spaces. These projects help by removing unnecessary items, organizing, cleaning, and maintaining an agreed standard.

Dining Services Storage 5S

Dining Services needed to create a more efficient and organized work space to gain more “free” space for the storage and processing of local foods.

Before

After

Before

After

Central Plant Office 5S

The Central Plant Office needed to organize drawers, cabinets, and paper files to reduce search time and make information easier to retrieve.

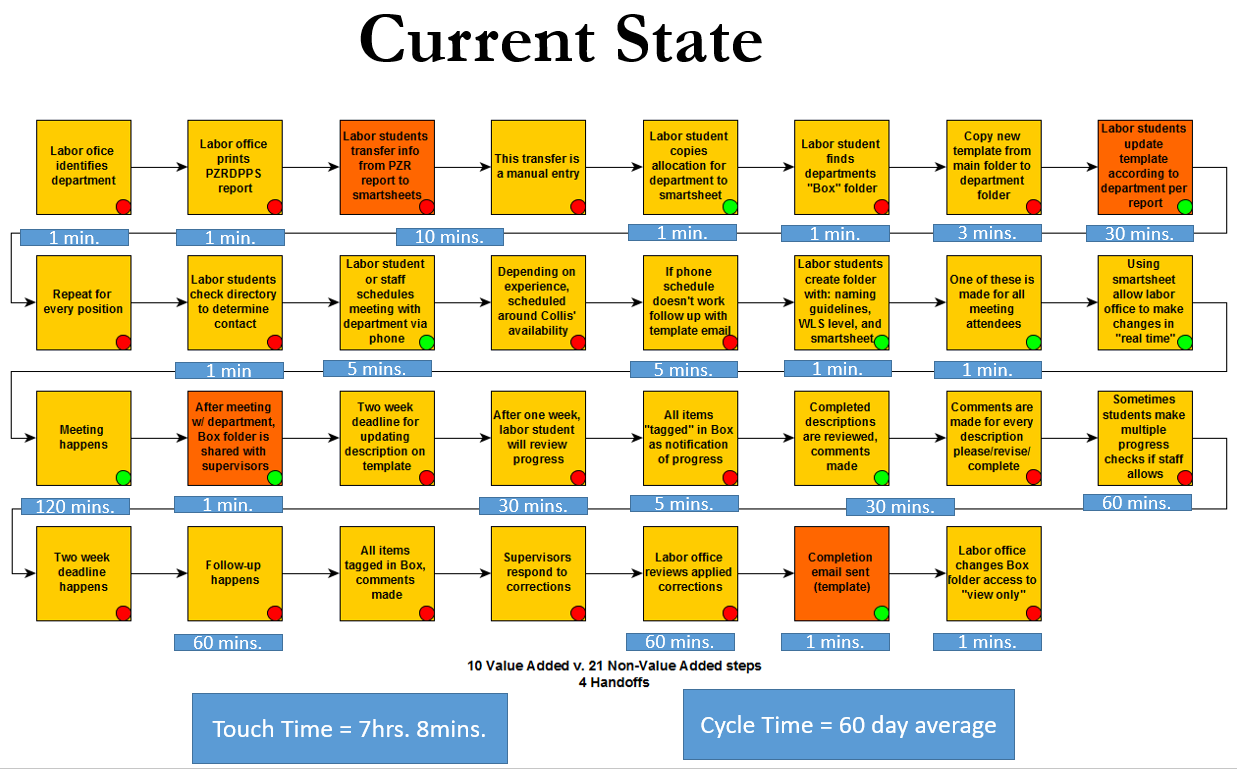

Value Stream Mapping

Value Stream Mapping projects focus on finding and removing pain points in a process. These projects are scoped out, important stakeholders are identified, current and future value stream maps are created, changes are implemented, results are tracked, and success is celebrated.

Labor Student Job Postings and Descriptions

Labor supervisors failed to understand the importance and need for accurate job descriptions. The process for updating and creating these was unclear and time consuming. Incomplete or missing job descriptions are a compliance violation and lead to misunderstandings between labor students and supervisors. The new process takes 75% less time for supervisors to complete and all involved staff can usually complete the process in one meeting.

“Wow. My department is finally ahead and we are doing things right as it relates to our job descriptions.”